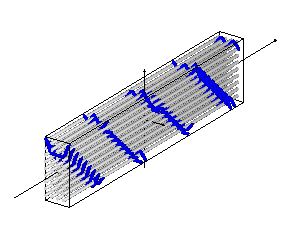

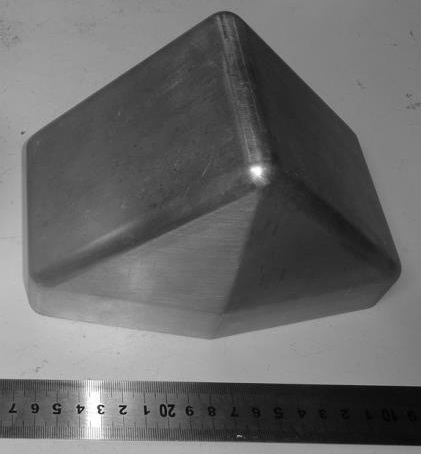

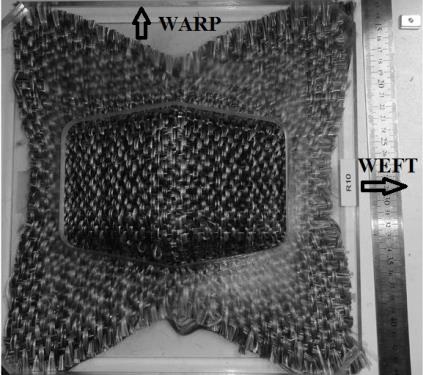

The quasi-static folding behaviour of 3D warp interlock fabrics have been done with several architectures and types of yarns to understand their deformation in the thickness along one of the two warp and weft fabric directions.

Considering the 3D warp interlock fabric made with 8K carbon yarns:

3D warp interlock A-L 3-2-9 – Binding {Twill 4 weft effect right shift} {1 11 21 31 – 2 12 22 32 – 3 13 23 33 – 4 14 24 34– 5 15 25 35 – 6 16 26 36– 7 17 27 37 – 8 18 28 38 – # – #} – Surface {plain weave} {10 20 30 40 – # – # – #- # – # – # – # – 9 19 29 39- #},

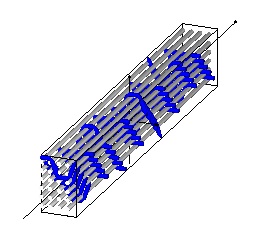

Weft yarns have been inserted per column in order to obtain the final fabric thickness.

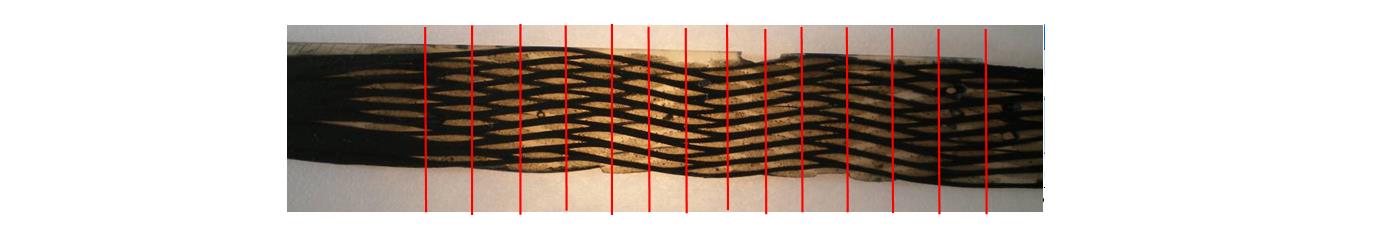

Different folding angles have been applied on the 3D warp interlock fabric to observe the fabric deformation in the warp direction by checking the evolution of the weft yarns columns position.

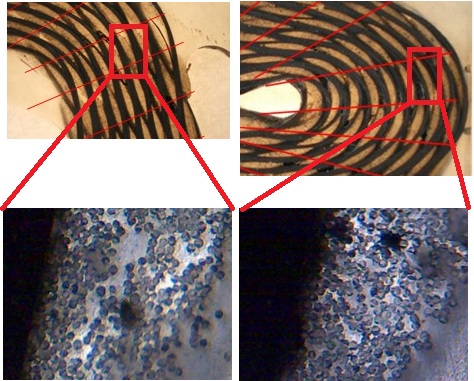

Cross section view of weft yarns with a folding angle value lower to 90°

Cross section view of weft yarns with a folding angle value up to 90°

Cross section view of weft yarns with a folding angle value equal to 180°

For two different values of the folding angle, the cross section shape of a carbon weft yarn has been observed globally (top of the view) and at the filament scale (down of the view). The increase of the folding angle value in the thickness of the 3D warp interlock fabric leads to the compaction of all the yarn’s filaments.

Considering the 3D warp interlock fabric made with 6K carbon warp yarns (200 Tex) and RC14 320 P109 fiberglass weft yarns (320 Tex):

3D warp interlock O – L 1-2-13 – Binding {plain weave} {1 13 – 2 14 – 3 15 – 4 16 – 5 17 – 6 18 – 7 19 – 8 20 – 9 21 – 10 22 – 11 23 – 12 24 – # – #}.

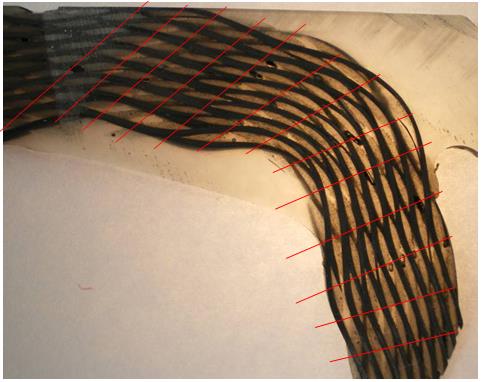

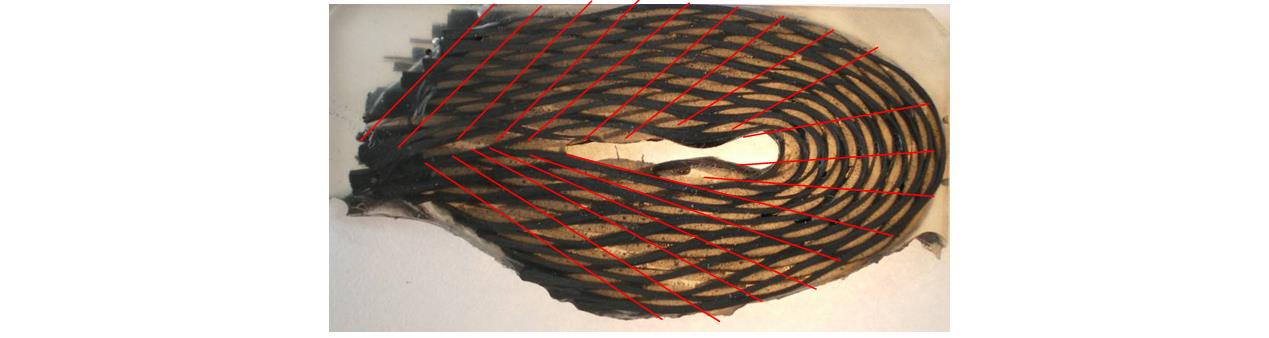

Different folding angles have been applied on the 3D warp interlock fabric to observe the fabric deformation in the weft direction by checking the evolution of the warp yarns columns position.

Cross section view of warp yarns with a folding angle value up to 90°

Cross section view of weft yarns with a folding angle value equal to 180°.

Boussu F, Legrand X, Nauman S, Binetruy C. Mouldability of angle interlock fabric. In FCPM 9, 9th international Conference on Flow Processes in Composite Materials; 8–10 July 2008; Montréal, Canada. p. 42.

Nawab N. Etude de moulabilité des tissus 3D multi-couches interlocks. Master MPT ENSAIT. Roubaix, France: ENSAIT laboratoire GEMTEX; 2009.

Nawab Y, Nauman S, Boussu F, Cristian I, Koncar V. Study of Mouldability of 3D Woven Multilayer Interlock reinforced Carbon-Epoxy Composites. In 7th International Bhurban conference on applied sciences and technology; 11-14 January 2010; Islamabad, Pakistan.

Nauman S. Geometrical modelling and characterization of 3D warp interlock composites and their on-line structural health monitoring using flexible textile sensors. Ph-D thesis. Lille: University of Lille 1; 24/03/2011.

Nauman S, Cristian I, Boussu F, Koncar V. In situ strain sensing in Three dimensional woven preform based composites using flexible tensile sensor. In 10th TEXCOMP International Conference on Textile Composites; October 26–28, 2010; Lille, France. p. 363-370.

Phone: (+33) 320256476

Mobile: (+33) 626883959

E-mail : (click to reveal e-mail)